Follow along: IG @birectifier

[If you are a distiller, make sure you know about the birectifier]

Vidal F., Parfait A., 1994. Introduction d’une levure à aptitude rhumière en fermentation de dérivés de la canne à sucre. BIOS Boissons 249, 21–26.

Introduction of a yeast with rum aptitude in fermentation of sugar cane derivatives

by

F. VIDAL* et A. PARFAIT**

* Centre Régional d’Innovation et de Transfert de Technologie-Biotechnologie et Agro-industries de la Caraïbe, BP n° 52, 971.52 Pointre-a-Pitre, GUADELOUPE FWI.

Summary

Rum is the most consumed white alcohol in the world. Among the different types of rums, traditional rums are all produced in the French overseas departments. In the French West Indies, rum technology has changed little. In distilleries, the largest losses happen in the fermentation workshops. Since the opening of the European market, the protection of French rums is less important and competition is becoming worrying. The reduction of losses and the regularity of production should allow local manufacturers to remain competitive. In this context, better control of the operations in the fermentation plants has become necessary. In the INRA yeast collection, a 493 yeast, adapted to the medium based on sugar cane gives interesting results in industrial distilleries. With very precise implementation conditions using an active dry yeast seeding technique, alcohol productivity gains can be estimated at 30%, which will have a direct impact on the cost price of rum. The working conditions at the factory will also be improved.

The diffusion of yeast 493 with its seeding technique is now acquired for the production of molasses rums. In an agricultural distillery, the problem is more complex because it is necessary to take into account the interactions between yeast and bacterial activities.

Introduction

Rum is the third most consumed spirits in the world. With more than 500 million liters of pure alcohol a year, it occupies 11.4% of the market on a par with liqueurs but after whiskeys (28%) and brandies (14%). The first white spirit consumed, it is progressing steadily in a global manner and remains, on the commercial front, an issue for the large multinational companies of brandies (1).

In the French West Indies, rum fermentation has been traditional since the 17th century; different types of rums are produced according to the raw material used. Their technical itineraries are presented on the diagram no. 1 (2). As provided by French legislation, they all come from a fermentation and distillation of cane juice or molasses or syrup from the manufacture of cane sugar. From a regulatory standpoint, rums must also meet “impurity” or non-alcohol content (ENA) levels that are presented in Table 1.

Currently, on the market, rums of molasses occupy a predominant place and more particularly so-called light rums; they are rums refined by extractive distillation which gives them a very neutral taste. They are then used for blends.

Agricultural rums are produced exclusively in the French overseas departments and may be subject to special protection with the establishment of a controlled designation of origin. Even if traditional rums production seems marginal, they remain very popular on the French market for their aromatic character.

State of the rum technology in Guadeloupe

In Guadeloupe, the annual production of rum is about 8,000,000 liters of pure alcohol (IPA) for 12 distilleries, which represents a significant component in the profitability of the sugar cane sector. The capacity of industrial units varies from 70,000 to 700,000 IAP for industrial distilleries ((3), (4)).

Rum technology has evolved, but among the main manufacturing stages, fermentation is the one that is the least controlled and that generates the most significant losses.

The fermentations are either spontaneous or activated by a complementary seeding of baker’s yeasts. They are carried out in 48 hours on untreated musts containing 90 to 140 g/l of sugars and giving wines containing 4 to 6.5% volume ethanol. Only nitrogen addition and acidification of the medium are carried out.

Seeding fermentation tanks is carried out according to different techniques: the process by tank-mother (generation of leaven on medium more or less aerated with concentrations in sugars close to 80 g/l), the bottom of tank (addition fresh must on a volume of wine not sent for distillation, rich in yeasts) and the cutting from a tank in the active phase of fermentation.

Whatever these techniques, the conditions for the implementation of leaven are poorly controlled and fermentation controls during manufacture are, when they exist, difficult to interpret.

The introduction of yeasts from bakeries (Saccharomyces cerevisiae) recommended in 1969 by MEJANE has made it possible to limit fermentation accidents but the ethanol yields obtained in distilleries are still low. Expressed in liters of alcohol per kg of reducing sugars, they are 0.52 for molasses and 0.47 for cane juice, whereas the theoretical yield according to PASTEUR is 0.643 IAP / kg (5).

According to TOURLIÈRE (6), a well conducted alcoholic fermentation should lead to a yield at least equal to 0.60 IAP / kg and any distiller should be able to get closer to this practical yield. ALARD and DE MINIAC (7) obtained yields of 0.62 IAP / kg on beet molasses.

Alcohol losses are expensive for distillers because they have a direct impact on the cost of rums, which are very high in the West Indies compared to other producing countries.

In this context, the introduction of a yeast adapted to rum fermentation was raised. The objectives are multiple: increase control of fermentations, reduce ethanol losses, limit bacterial contamination and improve working conditions in the distillery.

Introduction of a yeast selected distillery

We used yeasts from the INRA collection that were all isolated in production sites before the systematic introduction of baker’s yeasts.

During the laboratory selection, a Saccharomyces cerevisiae listed 493 was most active during the initial fermentation phase of cane juice and molasses with an interesting ethanol yield. These results were confirmed when comparing this 493 yeast with other commercial yeasts, including baker’s yeast used in the distillery (8).

Properties of yeast 493

A methodology has been put in place to characterize the strain at the microbiological and biochemical level, to compare its fermentative performances with those of other yeasts, and then to define the conditions for industrial implementation in the form of active dry yeasts. The goal is to make the most of the fermentative potential and technological interests of this strain. The work was carried out at three stages: laboratory, pilot and industrial.

The company LALLEMAND has been associated with these operations in the context of the production of strain 493 active dry form and in the comparative study of this yeast with yeasts of various origins belonging to their colleciontion

At pilot scale on molasses medium, experimental conditions have been established with reference to industrial conditions (9). We first validated the first results obtained on the capacities of the strain 493. Presented in the table no. 2, they show that the strain 493 has interesting fermentative potentialities on these media. Compared to baker’s yeast, Yeast 493 gives a yield and an ethanol productivity which are respectively 6.5% and 18.2% higher. The alcohol yields expressed in IAP / kg of reducing sugars observed confirm that the experimental conditions are close to the industrial reality since we obtain a yield of 0.524 for the baker’s yeast (corresponding to the figure announced at the industrial level).

To confirm the strong performance of yeast 493, a new comparative study was set up at the laboratory stage. Yeasts from the LALLEMAND collection have been selected according to their properties, either to withstand high temperatures or to support high osmotic pressure media such as strain no. 46 isolated by DE MINIAC from the National Union of Alcohol Distillers (10).

The results in table no. 3 confirm the previous outside observations. Strain 493 with yeast no. 46 are the most adapted to these types of environments; they give the best fermentation results. As a result of fermentation, the population level of strain 493 is very high, suggesting that its establishment and maintenance will be facilitated at the industrial level.

From a biochemical and microbiological point of view, the yeast 493 is a Saccharomyces cerevisiae var cerevisiae killer vis-à-vis the strain S6 and neutral to the strain 522D (toxin K2). Its pH and its optimum temperature. The growth rates are 4.5 and 33°C, which corresponds to the average fermentation conditions in the distillery.

The fermentative behavior of yeast 493 has been more specifically studied according to the density and temperature parameters which represent industrial constraints.

In distillery, the vat room is rarely equipped with cooling systems and it is common to note temperature rises reaching 36 to 37°C at the end of the exponential phase of fermentation. This lack of temperature regulation also conditions the low values of the initial densities of musts (1070).

Table 3- Comparison of yeasts in molasses fermentation at the laboratory

Table 4- Comparison of the serological balance between two processes: mother vat / baker’s yeast; pre-fermentation tank / yeast 493

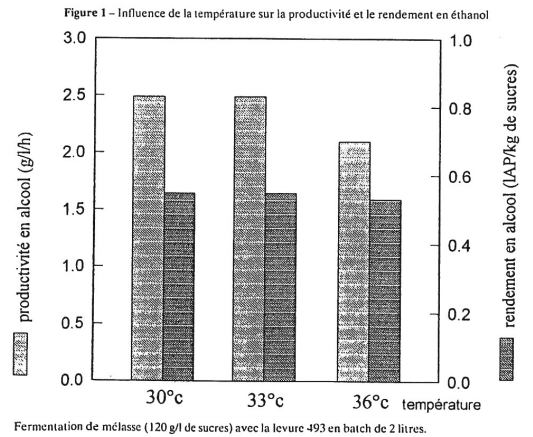

Yeast 493, for controlled fermentation temperatures at 30, 33 and 36°, retains good yields of alcohol (Figure 1). On the other hand, the ethanol productivities decrease by 18.5% when one goes from 33 to 36 ° C, because at this temperature, there is a slowing of the sugar consumption at the end of the fermentary phase (figure no. 2).

This yeast also produces, for musts with a concentration of sugars of 185 g/l (density 1102), wines grading up to 9.1% ethanol volume without modifying the yield of alcohol. Even if a drop in productivity of 20% is observed when passing sugar concentrations from 120 to 185 g/l (Figure 3), the operating time of the distillery would be significantly reduced (about 30%).

Due to its background, yeast 493 appears to possess a genetic ability to grow on sugarcane-based environments. By introducing this yeast, accepting both high temperatures and high osmotic pressures, the operating times of the plants could be reduced.

Yeast seeding technique

From an industrial point of view, the seeding technique is important both for the progress of the fermentation and for the quality of the rums.

In a molasses distillery, the most common seeding technique is the mother tank, which is used to generate a leaven. With this method, the amounts of yeast used in dry form are low; population levels and qualities of starters are not controlled as are the risks of contamination.

While considering the financial criterion, we recommended, after a series of pilot level trials on seeding techniques, a process that takes into account biological phenomena (yeast requirements, quality and quantity of leaven, implantation of strain, reduction of contamination) and working conditions in the distillery.

This process consists in replacing the mother vats with pre-fermentation vats which, when seeded at rates of 0.5 g/l with active dry yeasts, make it possible to obtain quickly a high level of high quality population. After fermentation (about 25% by volume), the progressive filling of the fresh must protects against excessive temperature rises which will directly affect the productivity of ethanol.

Figure 2-influence of temperature on density drop

Figure 3 – Influence of density on productivity and ethanol yield

Industrial tests

We conducted a week of trials in industrial distillery on the whole of the vat room which represents 24 fermentation tanks of 130 m³ each is the production of 190,000 IAP. Yeast 493 yeast / pre-fermentation tank gives very satisfactory results (Table 4). Alcohol yields (0.595 IAP / kg of fermentable sugars) have increased considerably. The average alcohol content of molasses wines of 6% ethanol volume (for a concentration of sugars of 100 g/l) is very reproducible with a coefficient of variation on the whole of the vat room of 2%. It can be estimated that between the gains obtained on the alcohol yield (14%) and on the occupation time of the vats (-17%), the total productivity gain of the plant will be greater than 30%.

Implantation and maintenance of strain 493, followed by pulsed-field electrophoresis chromosome migration technique (11), is greater than 90% at the end of fermentation with a 100% viability rate persisting during the first waiting phase before distillation.

From a qualitative point of view, the triangular tasting tests carried out with a jury of consumers show a homogeneity between the different batches of rums produced with the yeast 493. Compared to the rum produced with the baker’s yeast, it has a taste and a Balanced aroma with no bad taste.

Conclusion

The introduction of selected yeasts in rum fermentation is of interest only if it brings a reduction of the losses in the fermentation workshop and a better functionality of the factory. This is the case of the process that we recommend (use of pre-fermentation tank with seeding of yeast 493 in dry form activated) which gives good yields of alcohol and interesting gains in terms of productivity in industrial distillery which will have a direct impact on the cost price of rum. The organization of work in the fermentation workshop will be facilitated with the use of a single wort at a constant density and a rational adequacy between the preparation of the pre-fermentation tanks and the fermentation tanks. The risk of contamination is minimized by the lack of mixing of the tanks between them and the production should be regularized both quantitatively and qualitatively.

Even if the recommended process uses larger quantities of active dry yeasts than the conventional one, it can be estimated that, in the case of the distillery as an industrial support point and in its current operating conditions, the financial burden supplement should not exceed 10% of the profits obtained with the combined use of yeast 493 and the new seeding process.

Similar studies on cane juice are currently underway. A methodology on the seeding technique should be proposed to distillers respecting both the aromatic quality of agricultural rums and the reduction of ethanol losses. Here, the case is more complex because the fermentation results from an association of yeasts and bacteria responsible for the aroma so much sought after by informed consumers; this situation must be taken into account.

Thanks

We thank LALLEMAND SA, which gave us the benefit of its expertise in the introduction of selected yeasts in fermentative environments and which supported this work by taking charge of the development of industrial production technology in active dry form for yeast 493. Miss RAGINEL be thanked for her assistance in the comparative studies between yeast 493 and those in their collection.

Our thanks go to Prof. STREHAIANO and P. TAILLANDIER from ENSIGC’s Bioengineering Engineering Laboratory in Toulouse for their welcome and their technical and scientific supervision during the implementation verification studies of yeasts in industrial sites.

We thank Professor GOMA and his collaborators from the Department of Biochemical and Food Engineering of INSA Toulouse who have put the laboratory equipment at our disposal for some work.

We thank the distilleries of Guadeloupe who have made available their facilities for work on an industrial scale.

This work was funded in part by European support from the STRIDE Community Initiative Program.

Bibliographie

(1) (1993). — Le rhum : un marché potentiellement très concurrentiel. Revue de l’union patronale de la Guadeloupe, décembre, 12-16.

(2) PARFAIT A., SABIN G. (1975).– Les fermentations traditionnelles de mélasse et de jus de canne aux Antilles françaises. Ind. Alim., 92. 1,27-34.

(3) RANCE H. (1992). — Étude technico-économique de la filière rhum aux Antilles françaises. Rapport de stage CRITT-BAC Guadeloupe. IUT La Rochelle, 52 pages.

(4) (1993). — TER Guadeloupe, éditeur direction interrégionale INSEE Antilles Guyane.

(5) DESTRUHAUT C, FAHRASMANE L, PARFAIT A. (1986). — Technologie rhumière. Rapport de fin de convention INRA/Distillerie St James.

(6) TOURLIÈRE S. (1985). — L’éthanol de fermentation : ses possibilités, ses limites. Ind. Agric. Alim., 6, 749-753.

(7) ALARD G., DE MINIAC M. (1985). — Recyclage des vinasses ou de leurs condensats d’évaporation en fermentation alcoolique des produits sucriers lourds. Ind. Agric. Alim., 102,9,877-882.

(8) FAHRASMANE L. (1991). — Amélioration du rendement de la fermentation alcoolique sur milieu à base de canne à Sucre. 1° rencontre internationale en langue française sur la canne à sucre. Montpellier, France.

(9) VIDAL F, BONNEAU L., PARFAIT A. (1993). —Yeast and rum production: survey of some trials. Congress & Distilled beverage industry – Fermentation – Technology, 21-25 mai, Orlando, Etats-Unis.

(10) DE MINIAC M. (1987). — Sélection de souches de levures pour la fermentation alcoolique de milieux mélasses enrichis en nonsucre de vinasse. Ind. Agric, Alim, 5,425-439.

(11) BLONDIN B., VEZHINET F. (1988). — Identification de souches de levures œnologiques par leurs caryotypes obtenus en électrophorèse en champ pulsé. Rev. fr. oenol., 28,7-11.

2 thoughts on “Introduction of a yeast with rum aptitude in fermentation of sugar cane derivatives”